Today, businesses, communities, and organizations across the country are seeking to optimize their environmental and fiscal performance on multiple levels. Rethinking their waste by pursuing sustainable management methods and minimizing the waste that is disposed are – or should be – key considerations in this process.

What is waste minimization and why do organizations pursue it?

Waste minimization can be accomplished through a number of methods, including:

- Source Reduction and Reuse – Waste Prevention is the most preferred method to achieve waste minimization. It means reducing waste at the source to save natural resources, conserve energy, reduce pollution, reduce the toxicity of our waste, and save money for businesses and consumers. If you can’t prevent waste entirely, can it be reused such that durable goods can be reused for the same or an alternate purpose?

- Recycling – Materials that have an economic value if processed and used again in a new manufacturing process can often be recycled. Recycling requires organizations to segregate these materials from the waste stream and collect them separately. Recycling can be less costly than disposal because there is value in the collected materials; cleaner, more segregated, and properly packaged streams typically draw a higher value than mixed materials (e.g., baled cardboard is more valuable than a mixed paper stream collected in loose form).

- Composting – Materials with an organic content (i.e., food wastes, yard wastes, food-soiled paper, and disposable paper products not suitable for recycling) can be collected for composting. Composting – or advanced forms of biological degradation such as anaerobic digestion – provides for the monitored and controlled decomposition of organic materials, preserving the nutrients embedded in the material and producing a finished compost product that can be applied to fields, blended with soils, and sold to consumers to enrich planting areas.

Environmental benefits of waste minimization include:

- Preserving raw materials for productive use in manufacturing of new products

- Reducing the demand for virgin resources, preserving our valuable natural resources

- Reducing greenhouse gas emissions associated with mining and harvesting virgin materials

- Reducing greenhouse gas emissions associated with landfill disposal or waste incineration

- Reducing toxicity of the waste stream

Cost benefits of waste minimization include:

- Increased operations efficiencies due to reduced material or product loss

- Reduced disposal costs

- Increased customer confidence, resulting in positive organizational image

Other drivers for waste minimization include meeting corporate sustainability and zero waste goals, and complying with regulatory requirements. Additionally, a number of states have mandated increasing levels of waste diversion and the formation of waste diversion programs. These policies impact individual generators as well as local jurisdictions who often are monitoring and reporting on waste and diversion activity.

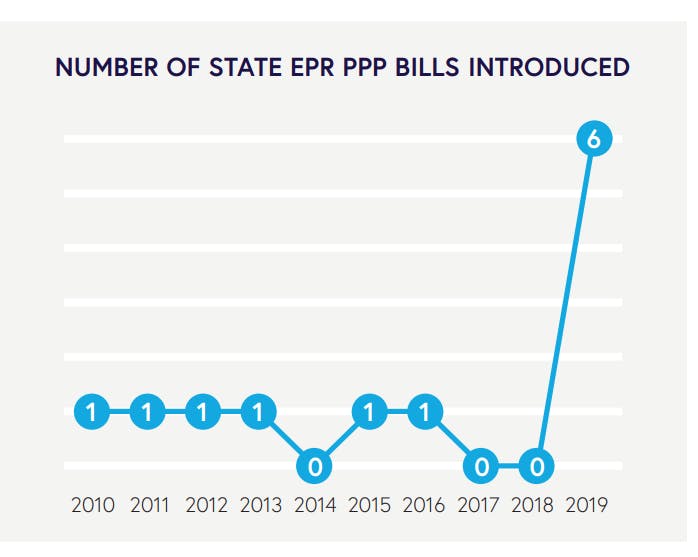

More recently, Extended Producer Responsibility (EPR) legislation targeting printed paper and packaging (PPP) has been introduced in at least 11 states during 2021 (recent bills are summarized here – https://www.rila.org/retail-compliance-center/epr-packaging-bills-introduced-to-states). This is a significant uptick from activity over the past decade, as shown in the figure below. EPR legislation places requirements on producers of products to take back and/or fund the recovery and recycling of their products. Paper and packaging EPR, where it is enacted, will impact a number of sectors, including retail, logistics, and manufacturing. APTIM is tracking this activity to advise and support our clients to comply with EPR requirements.